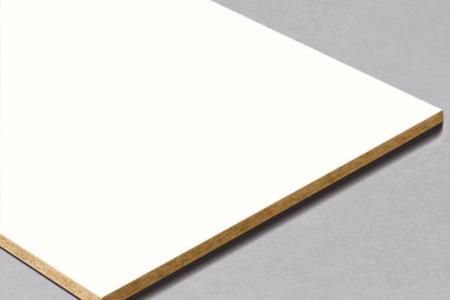

Hardboard

Hardboard panels are eco-certified composite products that have a high internal bond, exceptional stability, and smoothness ideal for paneling, furniture, fixtures, toys, general manufacturing, and applications where painting or die cutting is required.

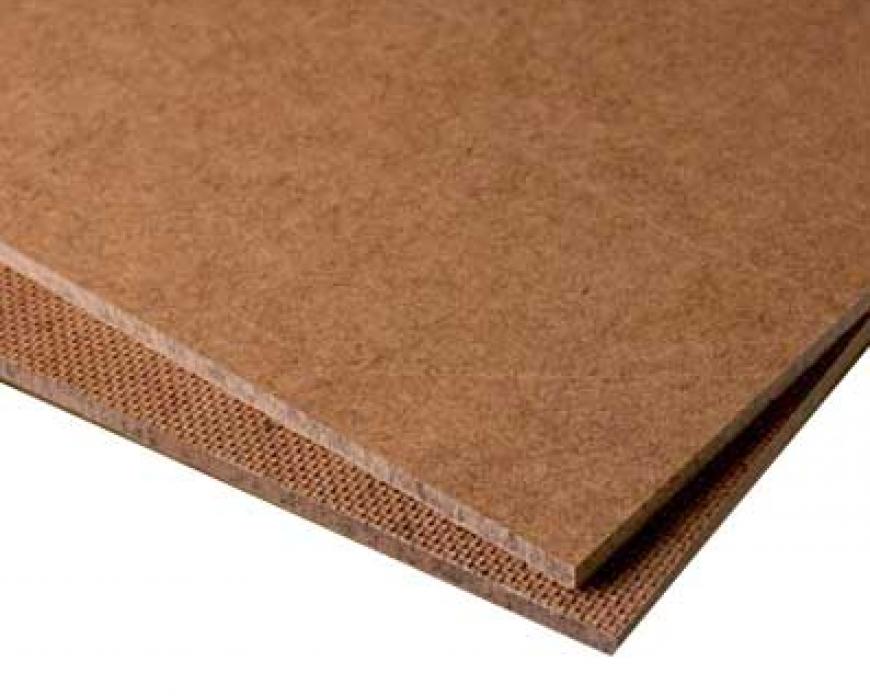

Hardboard is made of sawmill or forestry remainders. Using steam and heat, the wood is mechanically broken down into fibers. In the wet production process, the water is extracted from the pulp by pressing the pulp against a sieve and then pressed into panels under high pressure. The natural wood resin serves as an adhesive. In the dry production process, the fibers are first dried and then pressed together using additional resin adhesives to form a panel.

Hardboard has a uniform thickness, density and appearance that resists marring, scuffing and abrasion, as well as changes in temperature and humidity. Hardboard can be securely glued or fastened with screws, staples or nails and can meet a variety of customer needs.